- OPMAATZAGEN.nl

- DIY tips

What is MDF? Read all about MDF here!

What is MDF? Read all about MDF here!

Do you want to know more about MDF? In this article you will read all about it! We tell you what it is, what it is used for, what variants there are and how to order it to size!

What is MDF?

MDF is a board material made of small wood fibres that are pressed together. A resin is used as a binding agent. This board material is often used to make furniture and other interior applications.

The video on the right gives a brief explanation.

At OPMAATZAGEN.nl you can order mdf sawn or milled to size. We deliver within a few working days. Curious about our product range? Scroll further down or view all products via the button below.

The construction of MDF

As mentioned above, MDF consists of small wood fibres. This board material therefore falls under the category of fibreboards, just like chipboard, OSB, hardboard and softboard. Of all these variants, MDF uses the smallest wood fibres. You will therefore not easily see them in the board itself. The wood fibres are pressed under high pressure and temperature into a board. To keep the fibres together, a resin is added during this process. This also ensures that the top layers of this board material are fairly smooth.

The properties of MDF

Due to the small wood fibres, it has different properties than, for example, solid wood. For example, MDF does not splinter. This makes it very easy to saw and mill. In addition, MDF boards do not warp as boards made of natural materials do, for example: plywood or timber panels. It does react to heat and moisture, but instead of warping it will expand. MDF has a strong absorbing effect. This means that it attracts a lot of moisture, which is why untreated boards can only be used in dry areas and why a primer must always be applied before painting for a nice result. However, this does not apply to all MDF types, read more!

The variants of MDF

Because MDF is produced by machine, many properties can be modified during the production process. By adding substances or using a different type of resin or glue, various types are created. For example, certain negative characteristics can be remedied or MDF variants can be made for certain applications. We have listed the most important types.

Paint-bearing and primed MDF

Paint-bearing and Primed MDF are standard variants that can be painted over immediately. This means that you do not need to apply a primer to these variants! There is some difference between the two variants. Lacquer-bearing MDF, as the name suggests, has a lacquer-bearing film on the top layers; this layer is white and smooth. Ground MDF does not have a lacquer film but is sprayed with primer. This primer is somewhat stiffer and has a light grey colour. In practice, the difference between these two variants is not so great, but you can achieve a tighter result with a lacquer-carrying film.

Moisture retardant, Exterior and Tricoya MDF

MDF Moisture Resistant V313, MDF Exterior and MDF Tricoya are all variants that have been developed to be more resistant to moisture. The most common variant is MDF Damp-proof. This can be recognised by its green core and can be used in damp spaces indoors. Exterior MDF can be recognised by its dark brown core and can be applied outdoors. For the most extreme applications and weather conditions, there is MDF Tricoya.

Coloured MDF

Coloured MDF is a variant that has been coloured during the production process. As a result, the entire board is coloured through and through. The coloured MDF variants are never completely uniform; you can still see some wood fibres here and there. This gives the material a mixed appearance. The most well-known variant of coloured MDF is MDF Black Water-resistant. In addition to this variant, it is also available in grey, red, blue, yellow and brown.

Decorative MDF

Decorative MDF is a type of MDF that is provided with a top layer. This top layer finishes the material, so it does not need to be painted, although varnishing is recommended for a veneered top layer! With a melamine or HPL top layer this is no longer necessary. There are many different colours and structures available. For example, there are variants with a top layer in an even colour or with a look and structure of wood. Keep an eye on our product range for all available MDF variants.

MDF for special applications

In addition to all these types, there are also variants made for specific applications. For example, there is MDF Fire Retardant, a variant that burns noticeably less quickly and does not contribute to the spread of flame. This board material is coloured orange-red. In addition, there is, for example, MDF Ecologique, an MDF type that emits less formaldehyde than normal MDF.

The applications of MDF

Because of the many types of material, it also has many different applications. Of all these applications, there are a few that we see the most often.

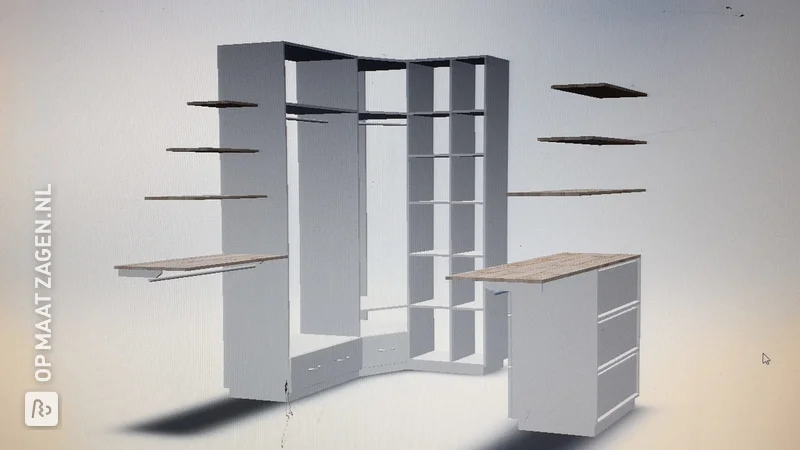

Furniture

MDF is the material of choice for making furniture. It is very strong, easy to work with and can be finished in various ways. We use this material a lot for our own custom-made furniture. You will see MDF in cabinets, sofas, beds, kitchens, tables and other interior applications. Kitchens and bathroom furniture are also made with MDF Moisture Proof. In the garden, MDF Exterior and MDF Tricoya are used in garden furniture.

DIY

Because it is so easy to process, it is also used in many DIY projects. You can easily edit the material yourself at home without the risk of damaging it.

A popular DIY project for which MDF is used is, for example, making speaker cabinets. Because you still have to make recesses to place the speaker in, it is a great advantage that this sheet material can be processed well. Other examples of DIY projects are doll's houses, photo frames and wall racks.

And more...

MDF board material has many more applications, some more creative than others. This work of art, for example, is made of MDF. Because there is a suitable variant for almost every situation, it can be used for many different projects. Have you also made something cool from MDF? Share it with us! We love to be inspired and to see other people's projects!

Working with MDF

In order to use MDF optimally, there are a number of things to bear in mind during processing. Here is a list of them:

- Before painting, it is important to first prime the paint. This way the paint adheres better and the material is also better protected against moisture.

- The ends need extra attention as they are even more susceptible to moisture. These can be treated with an edge sealer.

- Make sure it is not loaded too heavily. MDF will not break that easily, but it can bend. Once MDF is bent, it will not bend back again and that is a shame, of course. If you are going to put a heavy load on the MDF, sufficient support is therefore important.

Order customised MDF!

Do you want to get started? Then order it at OPMAATZAGEN.nl! Not only do we have a wide range of different types and thicknesses of MDF, we also cut your MDF to size! This means you don't have to use the sawing machine yourself and you only pay for what you actually need. We can have your order delivered within 3 working days! We are looking forward to seeing what you will make!

Also check out these similar DIY tips