- OPMAATZAGEN.nl

- Do it yourself

- DIY Projects

A self-made laundry room with lots of storage space, by Paul

Create this project yourself with sheet material cut to size by OPMAATZAGEN.nl!

Paul

Above average

4 minutes

Description by Paul

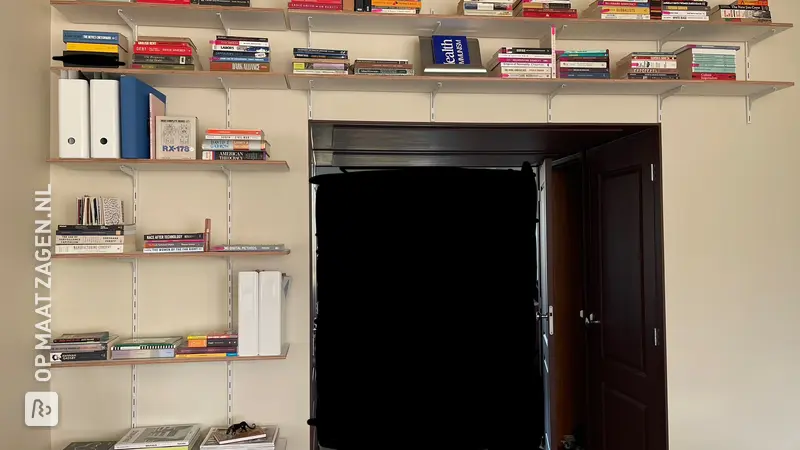

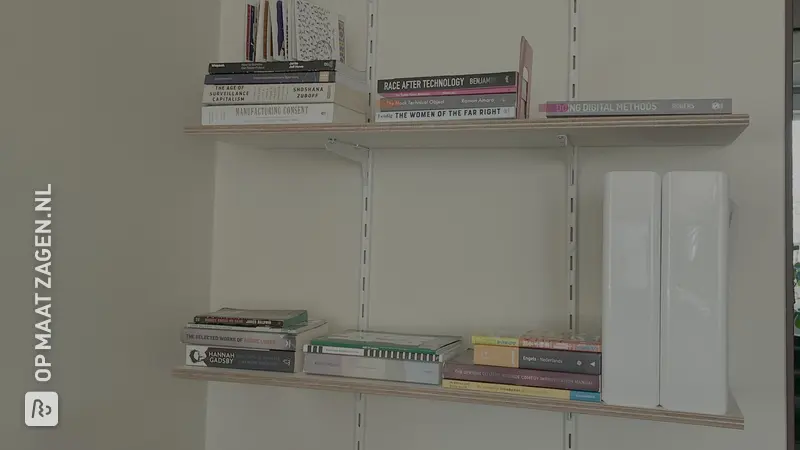

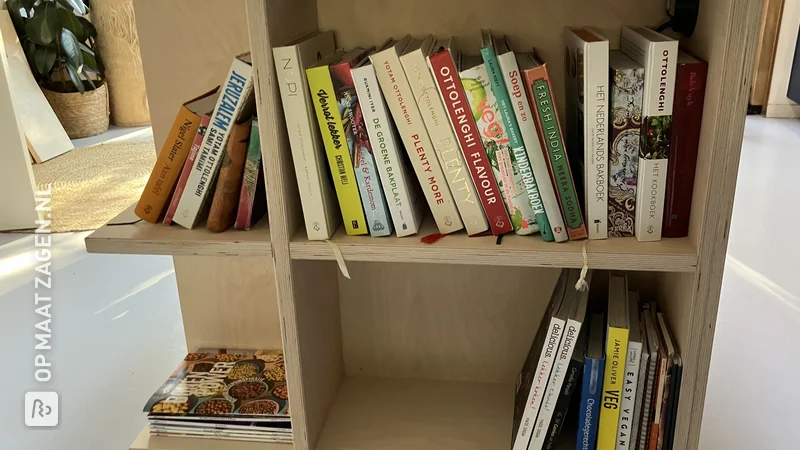

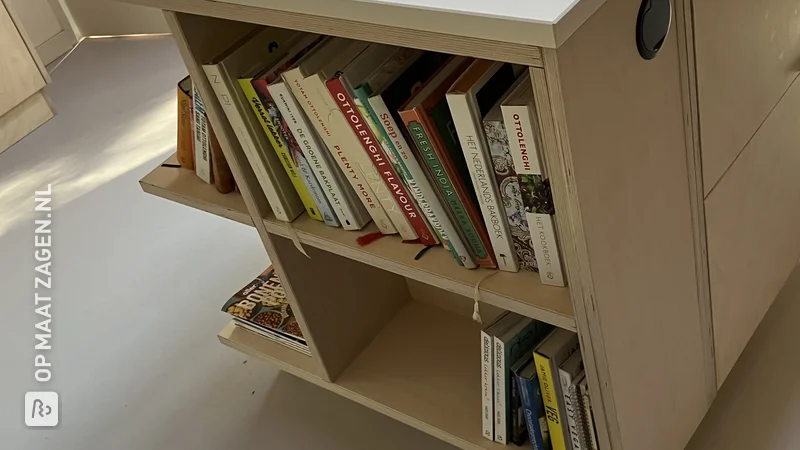

Our laundry room was run down and outdated and the space could be better utilized. Time for innovation! The room has a sloping wall with a skylight and a fountain and is intended for washing and drying. Very handy. We have moved the washing and drying machine to the low side so that a column of drawers can be placed next to it. The new worktop is higher than the old one so that drawers can also be created above the machines. In addition, the shelves on the wall have been renewed.

How I made this project

For the shelves, I had melamine chipboard cut to size and finished all around with edge banding (for the type we wanted was not (yet) available). The worktop is also made this way, but is thickened at the bottom with edgebanding before finishing. The thickening is visually important, but also constructively important for securing the hanging drawers. See photo of loading suspension. We initially had a rail system, but the new shelves are on loose supports so that they fit flush against the wall, are well secured and do not have to fit exactly between the rail and bracket. It also gives a calmer image. The drawer column is in a kind of kitchen cabinet frame. The drawers above the machines hang between vertical plates that are suspended from the top of the worktop. I made the thickening of the worktop and these load-bearing structures for the drawers from the cheapest type of 18 mm plywood I could find, namely underlayment. This is ugly, but you can't see it except for the front, which I finished with edging. The interior for the drawers is made of poplar plywood; the sides with which they hang from the guides are 15 mm, the bottoms and front and back sides are 12 mm. This makes them very light even though they are very spacious. Because they were cut to size, they were very easy to screw together with wood glue on the contact surfaces, making them indestructible. The fronts are made of the same material as the worktop and shelves. The beveled drawer hangs on the beveled side from a vertical plate that is in the middle of the drawer and is less deep than the other. The worktop rests on the sloping window sill of the skylight on one side and on the kitchen cabinet frame on the other. The fronts of the drawers are attached to the interior with long M4 bolts (sawn from a threaded rod because no available length) through the interior and front to the handles; and with 2 short M5 bolts through the interior that screw into a screw nut in the front in both bottom corners. Because the holes through the inner front are slightly larger than the bolts, this makes everything quickly and precisely adjustable. In addition to the wood from custom saws, I ordered (everything was easy to find): - Edgeband to match the melamine chipboard. - Drawer guides. - Handles. - 4 leveling feet with mounting blocks for the drawer column cabinet, and a pair of plinth clips. - Shelf supports. - Screws, wood glue, bolts, washers. - A bicycle inner tube. This is located between the dryer and the drawer column and helps keep the dryer in place. The valve is accessible behind the open drawers.

Dimensions of my DIY project

Worktop height 108.0 cm (bottom; thickness 36 mm) Drawers above machines WxH gross 60.0 x 23.0, net 59.0 x 22.0 Loading in column internal width 53.5; fronts wide gross 63.0, net 62.0; high twice gross 23.0, net 22.0; twice gross 26.0, net 25.0. Worktop 165.0 x 70.0. Depth of the drawers internally 65.2. This gives space for the front 18 mm, approx. 1 cm overhang of the worktop, and clearance at the back 2 cm. The drawer guides are 50.0 cm long and extend 100%. The dimensions of the planks seem very specific to me, but they are on the cutting list.

Tip! Also check out our handy DIY tips!

What now?

Want to make this DIY project? Check out Paul's saw list and complete your order easily.

€ 605,85

View all sheet materials